Maintenance Efficiency Achieved With Fieldpoint Oil And Gas Inspection Software

A Field Service Software Case Study Featuring: HighPoint Resources

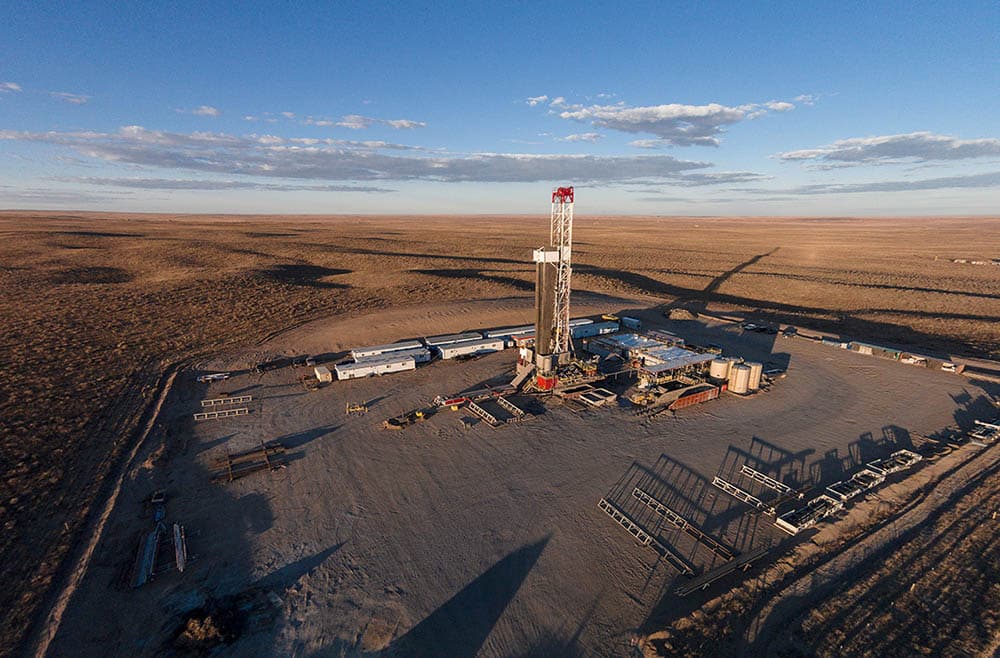

In the highly regulated oil and gas industry, HighPoint Resources (a Denver-based exploration, and production company that develops oil and natural gas assets in the Denver-Julesburg Basin of Colorado) is required by multiple regulatory agencies to have their sites and assets routinely inspected. Since early 2020, HighPoint has relied on Fieldpoint’s field service software and mobile capabilities to increase the efficiency of those inspections, the reporting of their results, and to better handle tracking of all their equipment.

From what was a completely paper-based process before deploying Fieldpoint, HighPoint is now managing over 450 service inspections each month across all their 190 sites. Covering more than 4,200 pieces of equipment with Fieldpoint’s mobile application in the hands of their inspection team, and a customized field service software that focused on numerous automated processes, Highpoint has improved efficiency throughout their inspection process.

We have to maintain compliance, and we have to demonstrate it to the regulatory agencies, the EPA, the State of Colorado. We have always done it, but we finally have it in one place now, where we can quickly inspect, record the data, and develop reporting on the backend. We always knew that once we had the solution, it would be efficient.

Digitizing Regulatory Compliance

Completing inspections on paper was an outdated process of performing compliance inspections, one that HighPoint wanted to avoid. Working in the oil and gas industry, inspection reports get dirty, they can be illegible, and data needs to be entered into a system for reporting purposes. For HighPoint, that system was a shared Excel spreadsheet that each technician was required to enter all their inspection report information into. This shared spreadsheet could only be accessed by one member at a time, so it was a time-consuming process to enter information that was required for each inspection.

“Writing on paper is effective, but once you’re done, the information just stays on the paper,” said Calhoun. “What Fieldpoint helped us do was to quickly track all that data. Now I can understand, with the click of a button, how many inspections my technicians are doing a day, what they are capable of, and exactly what they’re reporting as soon as they hook up to the cloud.”

If information were missing from a report, Calhoun said he would have to go through hundreds to thousands of paper inspection reports to find the information that was missing and enter it into the system they had established. It was a time-consuming process, both in the field and back in the office, to complete each inspection report, getting the information off the pages of reports and into the system to track all the data.

HighPoint’s inspection team now uses Fieldpoint’s mobile application in the field when completing inspections. Part of HighPoint’s implementation was to create a simpler process for their technicians to complete inspections, automating and auto-populating as much as possible. Inspection reports for HighPoint come pre-populated with the most likely answers to inspection questions, resulting in less manual effort from technicians in the field. When an issue is found, technicians can quickly use the mobile application to identify the issue, provide solution notes, take pictures, or video evidence, and repair the problem, such as leaks.

If a further repair is required, a work order is automatically generated for that site revisit, and Calhoun’s team either returns to solve the problem, or it is dispatched to another crew. It’s a system designed to reduce the workload of technicians in the field while maintaining the reporting standards needed to meet compliance. When the mobile application syncs with Fieldpoint’s field service software, all of the data and information is immediately available for reporting purposes.

“It makes us more efficient and we can do more with less people,” said Calhoun. “When we show up on site, we have predetermined some of those answers, because that’s how it should be. And you should only have to change it if there is a problem. It was all about efficiency.”

Fieldpoint Driving Reporting and Analytical Development

If HighPoint did not have to submit reports and track leaks, there would be no need for a compliance team, but due to heavy agency and government regulations, reporting is what drives them to even have the team in the first place. What has pushed them toward a better solution for tracking every inspection and site visit is greater visibility into their inspections and a more efficient way of producing the reports required to meet regulatory compliance.

Prior to implementing Fieldpoint, Calhoun would take the data that his compliance team had input into the spreadsheet and filter out the data he needed, which in turn, would be put into a new spreadsheet. He would then have to go over each paper inspection anyway because he needed times, which were not included in his spreadsheet. Over the course of six months, that is nearly 3,000 inspection reports he would need to go through to find times and any missing data to add to his reports.

Calhoun said he knew which reports he needed and the information in them, and now through Fieldpoint’s customized reporting, the information his compliance team enters using their tablets and the mobile application are able to feed those reports without him having to mold the data into the report he needs.

“Now we are pulling a report in Fieldpoint and it’s in the exact format I need,” said Calhoun. “It’s decreasing my workload, I’m able to take on other projects in the company, and it directly impacts my job. It’s night and day and it has decreased anxiety, frustration, and it has made my reporting life great.”

The side effect of this is that Calhoun is no longer spending time gathering data, but is now spending time analyzing the data he has gathered.

“I’m able to analyze the trends because Fieldpoint is tracking them by equipment,” said Calhoun. “We didn’t have that capability before. I didn’t have records of this specific piece of equipment over time, unless I went back and tried to reference every report we’ve submitted. So now, we have every piece of equipment. Moving forward from 2020, we’ll have years of data to analyze.”

Efficiency in Equipment Tracking

With 4,200 pieces of equipment to track and inspect across 190 sites, what was missing from HighPoint’s reporting was the ability to see what had happened to each piece of equipment. Using Fieldpoint’s contract system, HighPoint is tracking each piece of equipment and setting up preventative maintenance schedules for each, depending on the frequency of the inspection needed.

The effect is two-fold, in that the preventative maintenance schedule generates work orders automatically for each type of inspection, with the proper pre-determined answers to questions, or attached checklists, but also it keeps track of the maintenance being performed on each piece of equipment separately. This gives HighPoint greater insight into leaks and other repairs happening on each piece of equipment, enabling them to monitor trends and make changes to inspection frequency if needed on equipment that continuously doesn’t meet compliance.

“Now I’m going to be able to tell you exactly which pieces of equipment are the issue, and we can analyze the data and figure out why,” said Calhoun. “Being able to pull reports, instead of diving into spreadsheets and pieces of paper, really makes it more efficient to look at our equipment and forecast failure rates and what pieces of equipment seem to be holding up better in the field.”

Selecting a Customizable and Integrated Solution

When it came time to select a field service software, HighPoint looked at a few different options, but it was the ability to visualize what their system could look like within Fieldpoint that helped narrow the selection. HighPoint’s implementation required integration to a secondary system, SiteView, which houses all their site and equipment information, as well as levels of customization around their equipment tracking, scheduling, and offline capability.

Fieldpoint presented HighPoint with the ability to customize the field service software to reflect their business practices, as well as integrate with SiteView. Along the way, Fieldpoint and HighPoint worked together to develop customized workflows and unique solutions to data entry, scheduling, and work order automation.

“Everyone in the room could visualize that Fieldpoint could satisfy our needs with some customization,” said Calhoun. “Fieldpoint drove us toward a more standard solution if it could solve our issues. I can’t say enough great things about the end result and my job with Fieldpoint now. It took longer, but that’s because we customized it more to ensure ease now, to ensure the final product was the best we could get to.”

HighPoint is now looking at the potential to use Fieldpoint in other activities throughout the company, such as for their safety group who also needs to inspect each facility. Fieldpoint has brought on a change in business operations, as now HighPoint can focus more on the analysis of their data, as opposed to data collection, which will result in greater insight into their equipment and sites.

“The end product shows what it was all about and why it was worth it,” said Calhoun. “We’re already expanding capabilities as we address inefficiencies in the field. I can’t say for sure there will be more, but I certainly feel with the growth in Fieldpoint, it’s coming. It has to.”